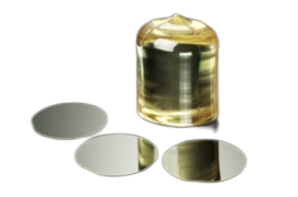

Lithium tantalate (LiTaO3)

LiTaO3

Lithium tantalate (LiTaO3) crystal is an excellent multifunctional material with high application value. LiTaO3 crystal has become the best choice of pyroelectric infrared detector materials due to its stable and high chemical properties (insoluble and water), Curie point higher than 600℃, not easy to depolarization phenomenon, low dielectric loss, and high optimal detection rate. The polished LT wafer is widely used in the manufacture of resonators, filters, transducers and other electronic communication devices, especially because of its good mechanical and electrical coupling, temperature coefficient and other comprehensive performance, it is used in the manufacture of high-frequency surface acoustic wave devices, and in many high-end communication fields such as mobile phones, walkie-talkies, satellite communications, aerospace and so on.

Download PDF

Product Detail

Fe doped LT Wafers

| Parameter |

Specification |

| Material |

LiTaO3 wafers(White or Black &Fe doped) |

| Diameter |

3inch/4inch/6inch |

| Diameter Tolerance |

±0.03mm |

| Curie Temp |

603±2℃ |

| Cutting Angle |

X/Y/Z/X112Y/Y36/Y42/Y48/etc |

| Tol(±) |

<0.20 mm |

| Thickness |

0.18 ~ 0.5mm or more |

| Primary Flat |

22mm /32mm /42.5mm /57.5mm |

| LTV (5mmx5mm) |

<1µm |

| TTV |

<3µm |

| BOW |

-30 |

| WARP |

<40µm |

| PLTV(<0.5um) |

≥95%(5mm*5mm) |

| Orientation Flat |

All available |

| Surface Type |

Single Side Polished(SSP) /Double Sides Polished(DSP) |

| Polished side Ra |

<0.5nm |

| Back Side Criteria |

General is 0.2-0.5µm or as customized |

| Edge Criteria |

R=0.2mm or Bullnose |

| Fe doped |

Fe doped for saw grade LN< wafers |

| Wafer Surface Criteria |

Transmissivity general:5.9x10-11-10 at 25℃ Transmissivity general:5.9x10-11-10 at 25℃ |

| Contamination None |

| Particles @>0.3 µm ≤30 |

| Scratch , Chipping None |

| Defect No edge cracks, scratches, saw marks, stains |

| Packing |

25pcs per box |

Optical Grade Lithium Tantalate Wafers

| Parameter |

Specification |

| Material |

LiTaO3 wafers(White or Black) |

| Diameter |

2inch/3inch/4inch |

| Diameter Tolerance |

±0.03mm |

| Curie Temp |

603±2℃ |

| Cutting Angle |

X/Y/Z etc. |

| Tol(±) |

<0.20 mm |

| Thickness |

0.18 ~ 0.5mm or more |

| Primary Flat |

16mm/22mm /32mm |

| TTV |

<3µm |

| BOW |

-30 |

| WARP |

<40µm |

| Surface Type |

Single Side Polished(SSP) /Double Sides Polished(DSP) |

| Polished side Ra |

<0.5nm |

| Back Side Criteria |

General is 0.2-0.5µm or as customized |

| Edge Criteria |

R=0.2mm or Bullnose |

| Optical doped |

Zn/MgO etc. |

| Wafer Surface Criteria |

Contamination None Contamination None |

| Particles @>0.3 µm ≤30 |

| Scratch , Chipping None |

| Defect No edge cracks, scratches, saw marks, stains |

| Packing |

25pcs per box |

SAW Grade Lithium Tantalate Wafers

| Parameter |

Specification |

| Material |

LiTaO3 wafers |

| Diameter |

3inch/4inch/6inch |

| Diameter Tolerance |

±0.03mm |

| Curie Temp |

603±2℃ |

| Cutting Angle |

X/Y/Z/X112Y/Y36/Y42/Y48/etc. |

| Tol(±) |

<0.20 mm |

| Thickness |

0.18 ~ 0.5mm or more |

| Primary Flat |

22mm /32mm /42.5mm /57.5mm |

| LTV (5mmx5mm) |

<1µm |

| TTV |

<3µm |

| BOW |

-30 |

| WARP |

<40µm |

| PLTV(<0.5um) |

≥95%(5mm*5mm) |

| Orientation Flat |

All available |

| Surface Type |

Single Side Polished(SSP) /Double Sides Polished(DSP) |

| Polished side Ra |

<0.5nm |

| Back Side Criteria |

General is 0.2-0.5µm or as customized |

| Edge Criteria |

R=0.2mm or Bullnose |

| Wafer Surface Criteria |

Transmissivity general:5.9x10-11-10 at 25℃ Transmissivity general:5.9x10-11-10 at 25℃ |

| Contamination None |

| Particles @>0.3 µm ≤30 |

| Scratch , Chipping None |

| Defect No edge cracks, scratches, saw marks, stains |

| Packing |

25pcs per box

|