1. The main raw material of glass is quartz sand, because the melting point of quartz sand is very high, so when melting, to add sodium carbonate, smelting into water glass, and then add calcium carbonate, let the two raw materials react together, it makes ordinary glass.

2. Glass is formed by the melting of sand and other chemical substances together (the main raw materials for production: soda ash, limestone, quartz), the formation of a continuous network structure in the melting process, the cooling process gradually increases the viscosity and hardening the crystallization of silicate non-metallic materials.

3.The chemical composition of ordinary glass is Na2O·CaO·6SiO2, the main component is silica, which is a kind of amorphous solid with irregular structure.

4. Raw material preprocessing - the massive raw materials (quartz sand, soda ash, limestone, feldspar, etc.) crushing, dry wet raw materials and treat iron containing raw materials for iron removal, to ensure the quality of glass.

5. Batch preparation

6. Smelting -glass compound is heated at high temperature (1550~1600 degrees) in the pool kiln or crucible kiln, so as to form a uniform, no bubbles, and meet the molding requirements of the liquid glass.

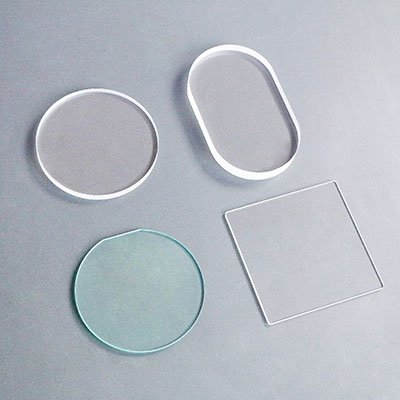

7. Moulding - Work liquid glass into the desired shape, such as plates, utensils, etc

8.Thermal treatment –Through annealing, quenching and other processes, eliminate or produce internal stress, phase separation or crystallization, and change the structural state of the glass.